Discussion on RFID testing technology

With the reduction of the price of readers and tags and the expansion of the global market, the application of radio frequency identification RFID (hereinafter referred to as RFID) is increasing day by day. Tags can be powered either by the reader (passive tags) or by the tag's on-board power supply (semi-active tags and active tags). Due to the reduced cost of subminiature passive CMOS tags, inventory and other applications are rapidly increasing. Some assessments suggest that as the price of passive tags continues to fall, almost every product sold will have an RFID tag on the inside. Due to the importance of passive RFID tags and the challenges of their unique engineering implementation, this article will focus on passive tag systems.

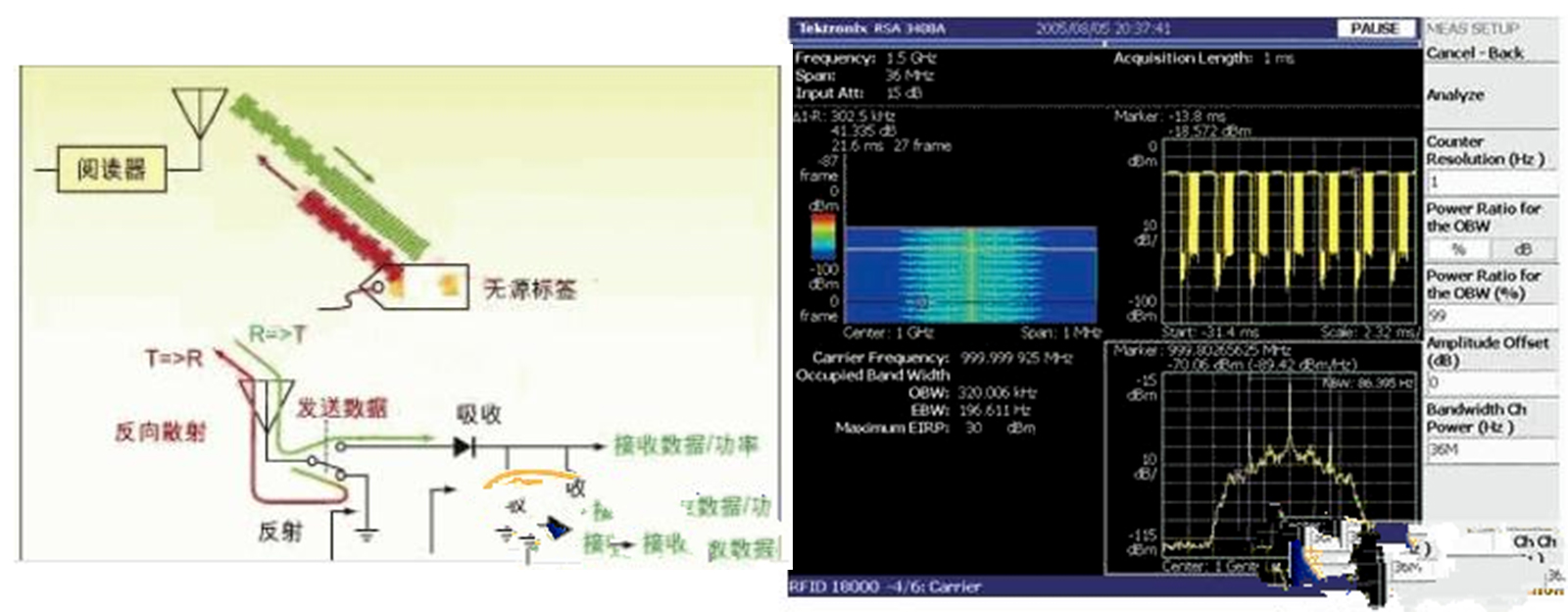

When a CW signal from a reader is received, the passive tag rectifies the radio frequency RF (hereafter referred to as RF) energy to generate a small fraction of the energy needed to keep the tag working, then changes the absorption characteristics of its antenna to modulate the signal and reflects it to the reader through backscatter [see Figure 1]. RFID systems typically use simple modulation techniques and coding schemes. However, simple modulation techniques are spectrally inefficient and require more RF bandwidth for a given data rate. Before modulation, the data must be encoded to form a continuous stream of information. There are many types of bit coding schemes available, each with its unique advantages of baseband spectral performance, the complexity of codecs and the difficulty of writing data to memory while driven by a clock. Passive tags have unique requirements for the encoding system used due to the difficulty of achieving the actual required accuracy with the timing source on the tag board, as well as challenging bandwidth requirements and maximizing RF energy transfer to supply energy to the tag. Finally, some sort of anti-collision protocol is required so that the reader can read all the tags within its coverage.

RFID Testing Review

Every RFID communication system must pass regulatory requirements and comply with the standards used. Today, however, system optimization separates the winners from the losers in this fast-growing industry. This article discusses the testing challenges faced by designers of RFID communication systems: regulatory testing, standards conformance, and optimization.

RFID technology presents several unusual engineering test challenges, such as instantaneous signals, bandwidth-inefficient modulation techniques, and backscatter data. Traditional swept tuned spectrum analyzers, vector signal analyzers, and oscilloscopes have been used in the development of wireless data links. However, there are some drawbacks to the use of these tools for RFID testing. Swept tuned spectrum analyzers struggle to accurately capture and characterize transient RF signals. Vector signal analyzers do not actually support spectrally inefficient RFID modulation techniques and special decoding requirements. Fast oscilloscopes have a small measurement dynamic range and do not have modulation and decoding capabilities. The Real-Time Spectrum Analyzer (RTSA) overcomes the limitations of these traditional test tools by optimizing transient signals and reliably triggering specific spectral events in complex, real-world spectral environments through Tektronix's patented frequency mask triggers.

Regulatory testing

Every manufacturer of electronic devices must meet the regulatory standards of where the equipment is sold or used. Many countries are revising regulations to keep pace with the unique data link characteristics of passive RFID tags. Most regulatory authorities prohibit CW emission of equipment unless it is used for short-term testing. Passive tags require the reader to send a CW signal to supply energy to the tag and backscatter it for modulation. Even if the passive tag does not have a typical transmitter, it can still emit a modulated signal. However, many regulations do not address modulation based on emitterless. Multiple spectrum emission tests are not explicitly included in RFID standards for readers, but they do become regulations.

Government regulations require control of the power, frequency, and bandwidth of the transmitted signal. These provisions prevent harmful interference and guarantee that each transmitter is a friendly neighbor to other users in the band. For many spectrum analyzers, especially swept spectrum analyzers that are typically used for pulsed signal energy measurements, making such measurements is challenging. The RTSA is capable of analyzing the energy characteristics of a complete packet transmission process and can also directly measure the carrier frequency of a frequency-hopping signal without having to center the signal over a span. At the touch of a button, the analyzer recognizes how an instantaneous RFID signal is modulated and enables regulatory measurements of power, frequency, and bandwidth, making the pre-compliance testing process flexible and convenient [see Figure 2]. Pre-conformance testing helps ensure that products pass conformance testing the first time, without the need for redesign and retesting.Standards conformance

Reliable interaction between readers and tags requires alignment with industry standards such as ISO 18000-6 C Type Specification. The requirement adds a number of tests that go beyond the basic requirements to meet the government's spectrum emission requirements. RF conformance testing is critical to ensure reliable interoperability between tags and readers.

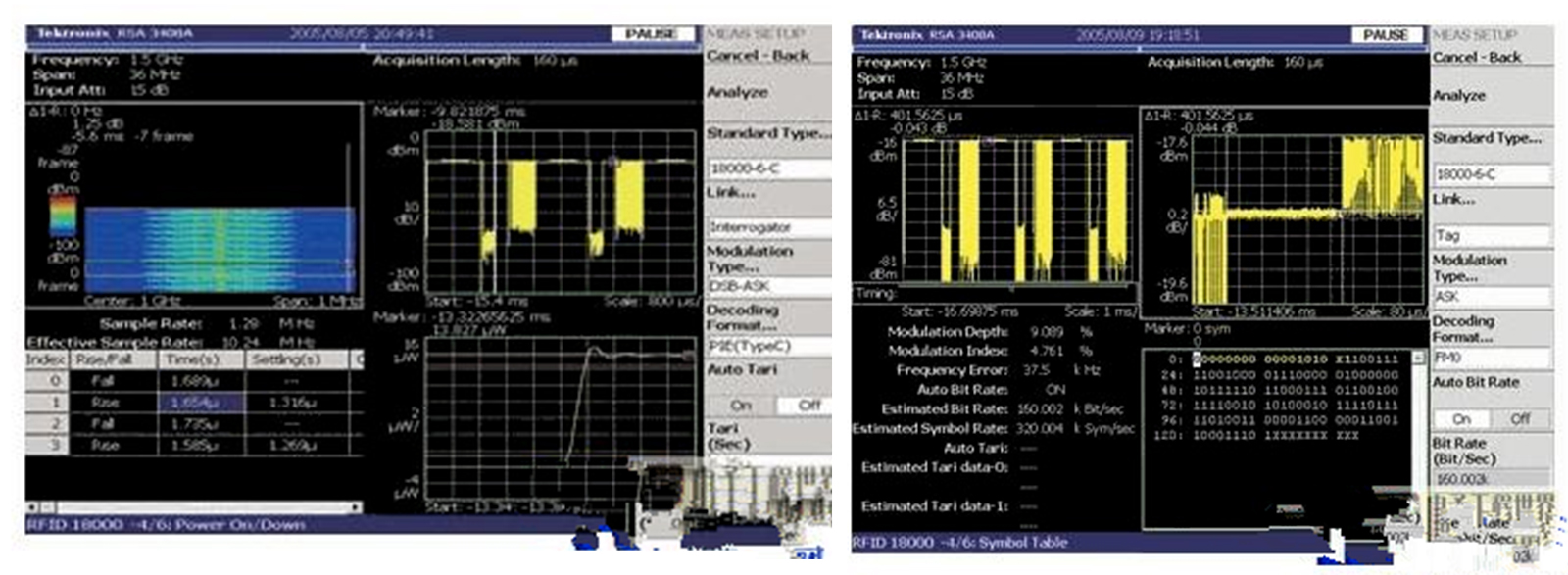

Pre-programmed measurements reduce the settling time required to perform these tests. For example, an important measurement for the ISO18000-6 C type is start-up time and shutdown time. The carrier energy rise time must be fast enough for the tag to collect enough energy for it to function properly. The signal must also reach a steady state quickly. At the end of the transmission, the carrier energy drop time must be fast enough to prevent interference with other transmissions.

Some RFID devices use dedicated communication mechanisms that are optimized for specific applications. In this case, engineers need an analyzer that can provide a variety of modulation and coding mechanisms that can be programmed to adjust according to the specific format being used.

optimize

Once the basic specifications have been met, it is important to optimize the performance of RFID products to gain a competitive advantage in a particular market space. Performance metrics include the read speed of the tag, the tag's ability to work in a multi-reader environment, and the distance between the tag and the reader. In consumer applications, the speed of communication between the tag and the reader has a direct impact on user satisfaction. For example, in the public transportation industry, where RFID is used, it is only widely accepted that the read time has been reduced from 5 seconds to less than half a second. In industrial applications, speed means throughput: the higher the throughput, the more efficient the use of capital and human resources. Since passive tags get the energy they need from RFID readers to function properly, multiple readers can cause the tag to try to respond to every reader that asks it. In the case of multiple readers, some anti-collision protocol is required to improve the throughput of the system. Finally, in order to maximize the read range of the tag, the carrier to noise requirement should be minimized, but this may conflict with the need to prevent the tag from running out of energy by minimizing the carrier downtime. These optimizations pose challenges for engineers and measuring equipment.

Let's look at a specific example – optimizing communication speed, also known as Flip Time TAT (hereafter referred to as TAT). Available RF energy, path fading, and altered symbol rates can improve the response time of tags to reader queries. The slower the response, the longer it will take to read multiple tags. Rapid measurement of TAT is necessary to optimize the speed of RFID systems.

TAT can be easily measured using RTSA [see Figure 4]. First, you'll need to install a frequency template trigger to get the entire query between the label and the reader. The RTSA's power-to-time view enables the user to watch the entire launch process. It is customary to think that the TAT of a half-duplex system is the time between the end of one downlink transmission (from the reader to the tag) and the start of the next downlink transmission. TAT time can be accurately measured by placing one marker at the end of the label interrogation and a second δ marker at the end of the backscatter or at the beginning of the next data emission by the reader. Maintaining the shortest TAT over a wide range of downlinks will help maximize system throughput.

RTSA can also demodulate symbols or bits associated with tag queries. The user only needs to select the appropriate RFID standard, modulation type, and decoding format. The analyzer automatically detects and displays the bit rate of the link. To further improve the productivity of engineers, the recovered data symbols were color-coded based on features. RTSA is able to automatically identify the preamble and color those symbols with $. This makes it easy to identify the actual data load and compare it with known values.

In summary, the RFID industry encompasses a large number of technologies and applications, many of which are different from typical communication links. Engineers need tools that can quickly and easily perform regulatory testing, standards conformance, and optimized measurements.

RSA3408A is a tool to meet these needs, supporting multiple RFID international standards, time-correlated multi-domain measurements, customized RFID communication architectures, and demodulation and symbol decoding of multiple RFID signals. The instrument greatly improves engineering efficiency while reducing the time to market. Whether it's meeting government spectrum regulations, ensuring that tags or readers comply with specific communication standards, or debugging a development issue, RTSA is a unique tool for analyzing RFID signals emitted by readers and tags.

-

What does the IoT EPC consist?What is the architecture of an IoT EPC? RFID systems are indispensable! With the acceleration of global economic integration and information networking, in order to meet the identific

What does the IoT EPC consist?What is the architecture of an IoT EPC? RFID systems are indispensable! With the acceleration of global economic integration and information networking, in order to meet the identific -

Industrial identification RFIDIndustrial identification RFID: industrial RFID example explanation China is a big industrial country, and industrial manufacturing is gradually moving towards intelligent manufacturing, creati

Industrial identification RFIDIndustrial identification RFID: industrial RFID example explanation China is a big industrial country, and industrial manufacturing is gradually moving towards intelligent manufacturing, creati -

Discussion on RFID Testing Technology of Radio Frequency IdentificationDiscussion on RFID testing technologyWith the reduction of the price of readers and tags and the expansion of the global market, the application of radio frequency identification RFID (hereinafter ref

Discussion on RFID Testing Technology of Radio Frequency IdentificationDiscussion on RFID testing technologyWith the reduction of the price of readers and tags and the expansion of the global market, the application of radio frequency identification RFID (hereinafter ref -

Lora Network Technology BriefWhat is LoRa and LoRaWAN LoRa is a physical layer or wireless modulation to create a long-distance communication connection, LoRa technology based on CSS modulation technology (Chirp Spread Spe

Lora Network Technology BriefWhat is LoRa and LoRaWAN LoRa is a physical layer or wireless modulation to create a long-distance communication connection, LoRa technology based on CSS modulation technology (Chirp Spread Spe