RFID empowers the application of various fields in the tobacco industry

In accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization and intelligence" to transform, improve, integrate and upgrade the warehousing resources, and build an integrated platform of upper and lower penetration, left and right coordination, resource sharing and configuration optimization based on the management idea of "demand-driven and order-driven", so as to realize the business refinement, operation automation, intelligent scheduling, scientific decision-making and management and control integration of warehouse management.

The business scope covered by the system is all the warehousing business of cigarettes, raw materials, auxiliary materials, pallets, recycled cigarette boxes and other materials in a China Tobacco Co., Ltd., including the factories of a China Tobacco Co., Ltd.

Through the construction of the project, adhering to the concept of "system concept", based on the warehousing business and focusing on the logistics supply chain, the company has built an integrated logistics management and control platform of the company that is "deep to the operation layer and control to the whole field", so as to realize the operation and management of logistics and warehousing business "one network and one management to the end". The information chain connects the company, the factory, the warehouse and the related parties, the business chain connects the production, supply, storage, transportation and finance, and the information source includes data, images and graphs.

Tobacco Cultivation & Acquisition Management:

At the tobacco planting stage, RFID technology can be used to identify and track tobacco fields and crop information, ensuring transparency and standardization of the planting process.

In the process of tobacco leaf purchase, RFID tags are used to uniquely identify tobacco leaves, which is convenient for subsequent variety identification, quality traceability and inventory management.

Tobacco production process monitoring:

In the tobacco production process, RFID technology can be used for automatic identification and traceability of tobacco leaves to ensure the quality and safety of products. By attaching an RFID tag with a unique identification code to each tobacco leaf, each tobacco leaf can be tracked and recorded, thus achieving comprehensive control and supervision of the tobacco production process.

RFID technology can also be combined with the tobacco industry's cigarette production and operation decision management system project (i.e., the No. 1 project) to achieve the function of "one dozen and two scans", that is, to paste a bar code on each cigarette produced, and carry out outbound scanning and warehousing scanning, so that the tobacco authorities can timely grasp the purchase, production and sales information.

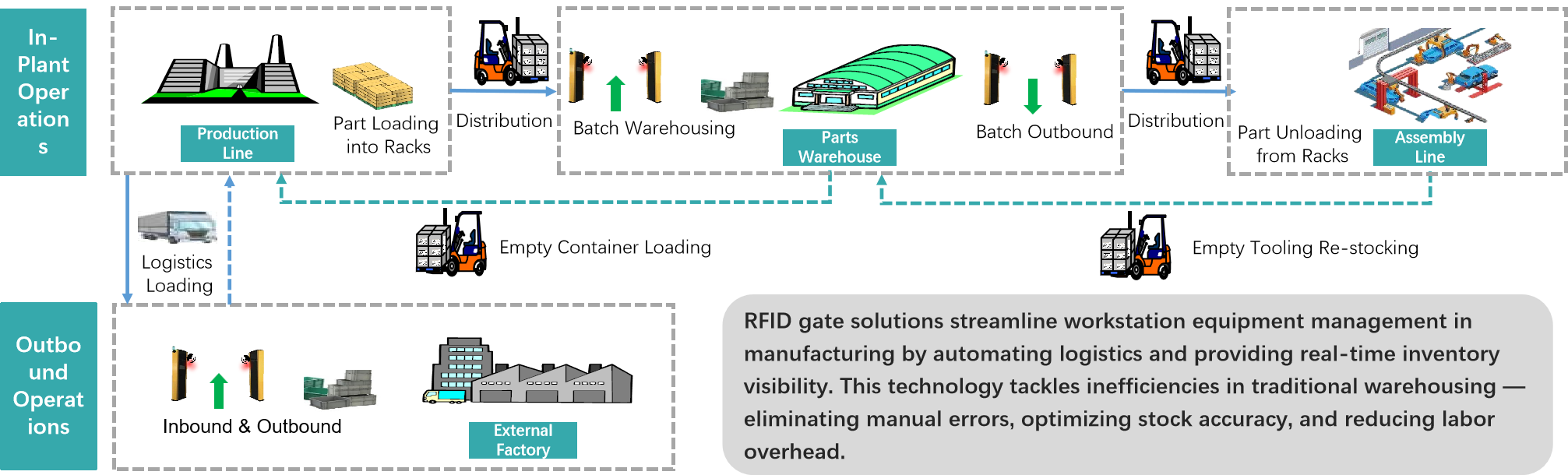

Tobacco Warehousing & Logistics Management:

In the tobacco warehouse, by attaching RFID tags to each cigarette box or cigarette pack, the inventory situation can be monitored and managed in real time, reducing errors and omissions in manual records, and improving the accuracy and efficiency of inventory management.

In the logistics process, by binding the RFID tags on the tobacco products and the transportation vehicles, the location and transportation of the goods can be tracked in real time, improving the efficiency and accuracy of logistics management.

Product Traceability & Anti-Counterfeiting:

RFID technology makes it possible to trace the entire process from tobacco production to sales, helping to combat counterfeit products and protect consumer rights.

By recording the whole life cycle information of tobacco products, RFID technology provides consumers with more reliable product traceability services, enhancing consumer trust and satisfaction.

Supply Chain Optimization:

RFID technology can optimize all aspects of the tobacco supply chain, improve the responsiveness and flexibility of the supply chain, and reduce operating costs.

By acquiring and analyzing supply chain data in real time, companies can better develop production and sales strategies and improve market competitiveness.

The application of RFID technology in the field of tobacco is of great significance for improving the informatization level of the tobacco industry, optimizing resource allocation and improving management efficiency. With the continuous progress of technology and the continuous expansion of application scenarios, the application prospect of RFID in the field of tobacco will be broader.

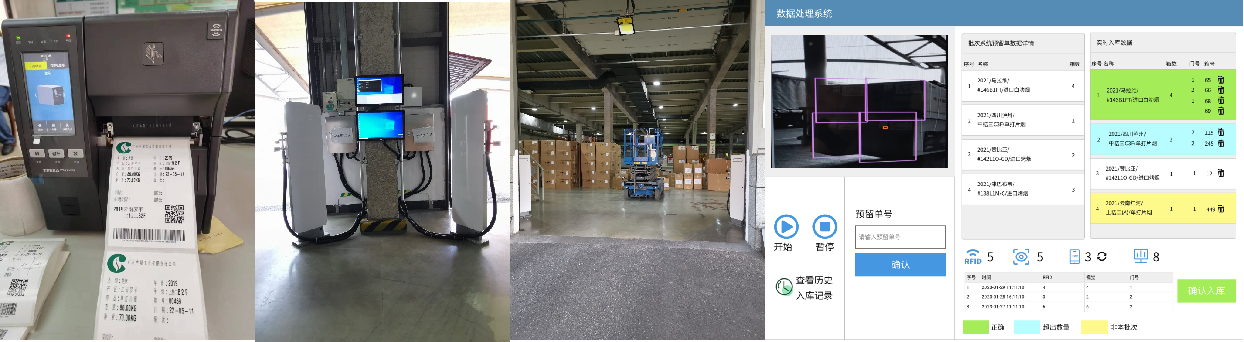

The formula library (raw material tobacco leaves) of a China Tobacco company can reduce the cumbersome operation of manual verification when the raw materials in the formula library are stored through the Internet of Things technology, and have in-depth discussions. In the end, it was decided to use the dual verification method of RFID channel door and machine vision to carry out the implementation, and now the construction of the scene and the technology research and development have been completed, and it is being put into operation.

-

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia -

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety -

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir -

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a