The online monitoring of LoRa+ sensors makes the safe production of the warehouse safer

The guardian of the safety of large vertical shelves

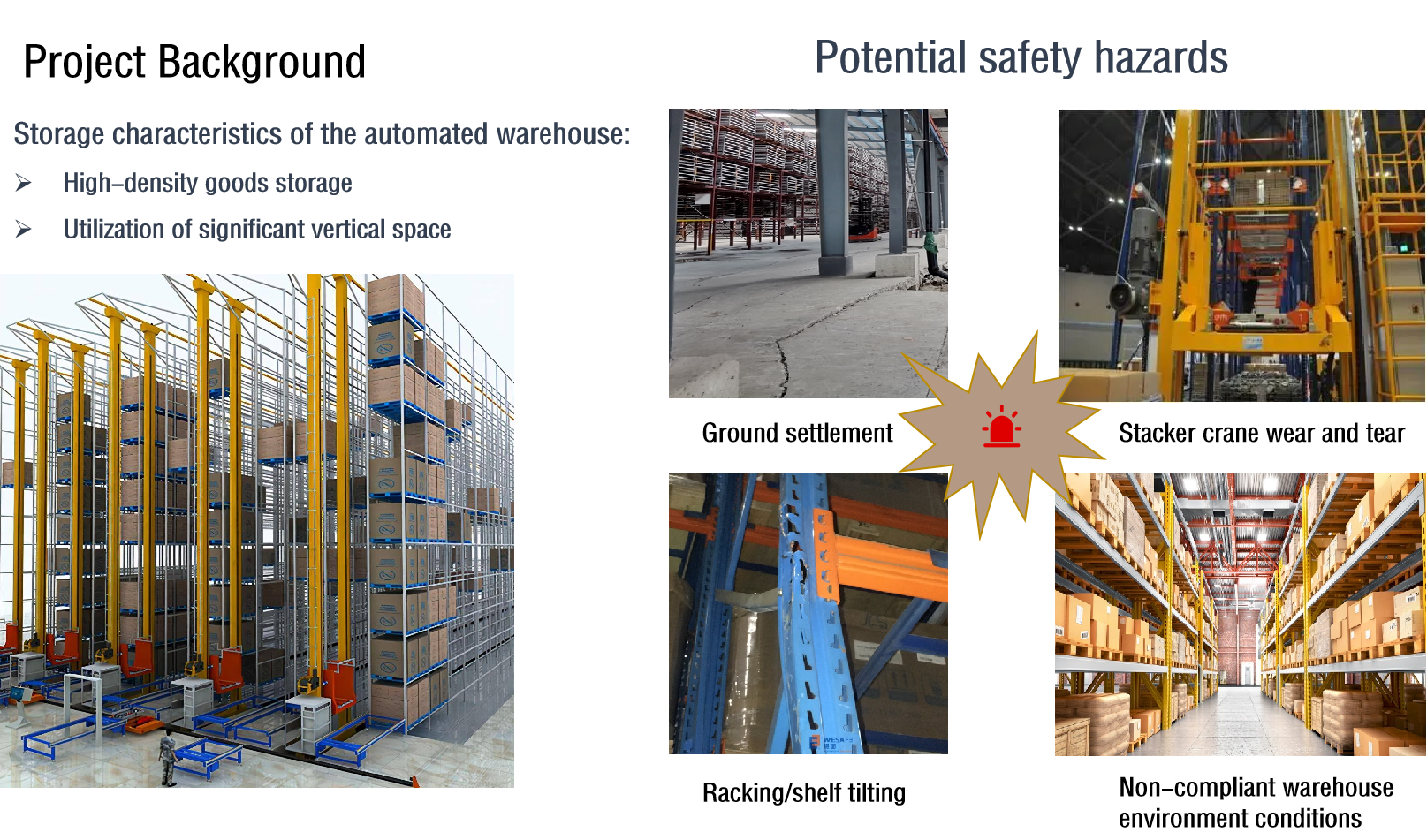

In the modern logistics and warehousing industry, the safety of large vertical shelves is very important as a key facility for storing goods. With the continuous expansion of warehousing scale and the increase of cargo storage capacity, real-time and accurate monitoring of shelf status has become a necessary condition to ensure the smooth progress of warehousing operations. The advent of LoRa+ sensors provides an efficient and reliable solution for large-scale vertical shelf monitoring.

First, the working principle

The LOAR network + sensor, that is, the chirp continuous wave radar sensor, works by transmitting a continuous chirp signal and receiving the signal reflected back from the target. By calculating the frequency difference between the transmitted and received signals, the distance between the sensor and the target object can be accurately measured. In the monitoring of large-scale vertical warehouse shelves, the sensor can monitor the distance changes between each part of the shelf and the surrounding environment in real time, as well as the deformation of the shelf structural parts themselves.

2. Advantages of LoRa+ sensors in large-scale vertical warehouse shelf monitoring

High-precision monitoring: The sensor can achieve millimeter-level distance measurement accuracy, accurately capture the subtle deformation and displacement of the shelf, and discover potential safety hazards in time. Whether it is the slow deformation of the shelf due to the long-term carrying of goods, or the instantaneous displacement caused by accidental collision, it cannot escape its "sharp eyes".

Non-contact detection: The sensor adopts non-contact measurement method, without direct contact with the shelf, which avoids additional damage to the shelf structure, and is not affected by the surface material, shape and other factors of the shelf, and is suitable for various types of large vertical shelves.

Strong environmental adaptability: The storage environment is complex, and there may be interference factors such as dust, moisture, and temperature changes. LoRa+ sensors have excellent environmental adaptability and can work stably in harsh environments, ensuring the accuracy and reliability of monitoring data. Even in high-dust warehouses, it functions and continues to keep shelves safe.

Real-time monitoring and early warning: LoRa+ sensors can collect shelf status data in real time, and through data analysis and processing, when abnormal shelf status is found, it can immediately send out early warning signals. According to the early warning information, the management personnel can take timely measures to deal with it, effectively avoid the occurrence of serious accidents such as shelf collapse, and ensure the safety of personnel and goods.

3. Application scenarios

1. Monitoring of daily warehousing operations: During the daily storage and handling of goods, LoRa+ sensors can monitor the force and deformation status of the shelves in real time to ensure that the shelves operate within the normal working range. As soon as the shelves are found to be overloaded or structurally unstable, the system immediately sends out an alarm to remind the staff to adjust the placement of goods or carry out shelving maintenance.

2. Emergency monitoring of natural disasters such as earthquakes: When natural disasters such as earthquakes occur, large vertical shelves may be shaken violently, resulting in structural damage. LoRa+ sensors can respond quickly, monitor the displacement and tilt angle of shelves in real time, provide key data support for emergency rescue, help rescuers judge the safety status of shelves, and formulate reasonable rescue plans.

Fourth, actual cases

A large-scale e-commerce logistics center has a large-scale automated three-dimensional warehouse. Before the introduction of LoRa+ sensors, due to the difficulty of grasping the health status of shelves in real time, there were accidents where goods fell due to local deformation of shelves, resulting in certain economic losses. After installing the LoRa+ sensor, the system monitors the shelves in real-time 24 hours a day. Once, the sensor detected a slight deformation of the supporting structure of the shelf in a certain area, and the system immediately issued an early warning. The staff responded quickly, adjusted the goods in the area, and strengthened and repaired the shelves, successfully avoiding a possible shelf collapse accident and ensuring the safe and efficient operation of the storage operation.

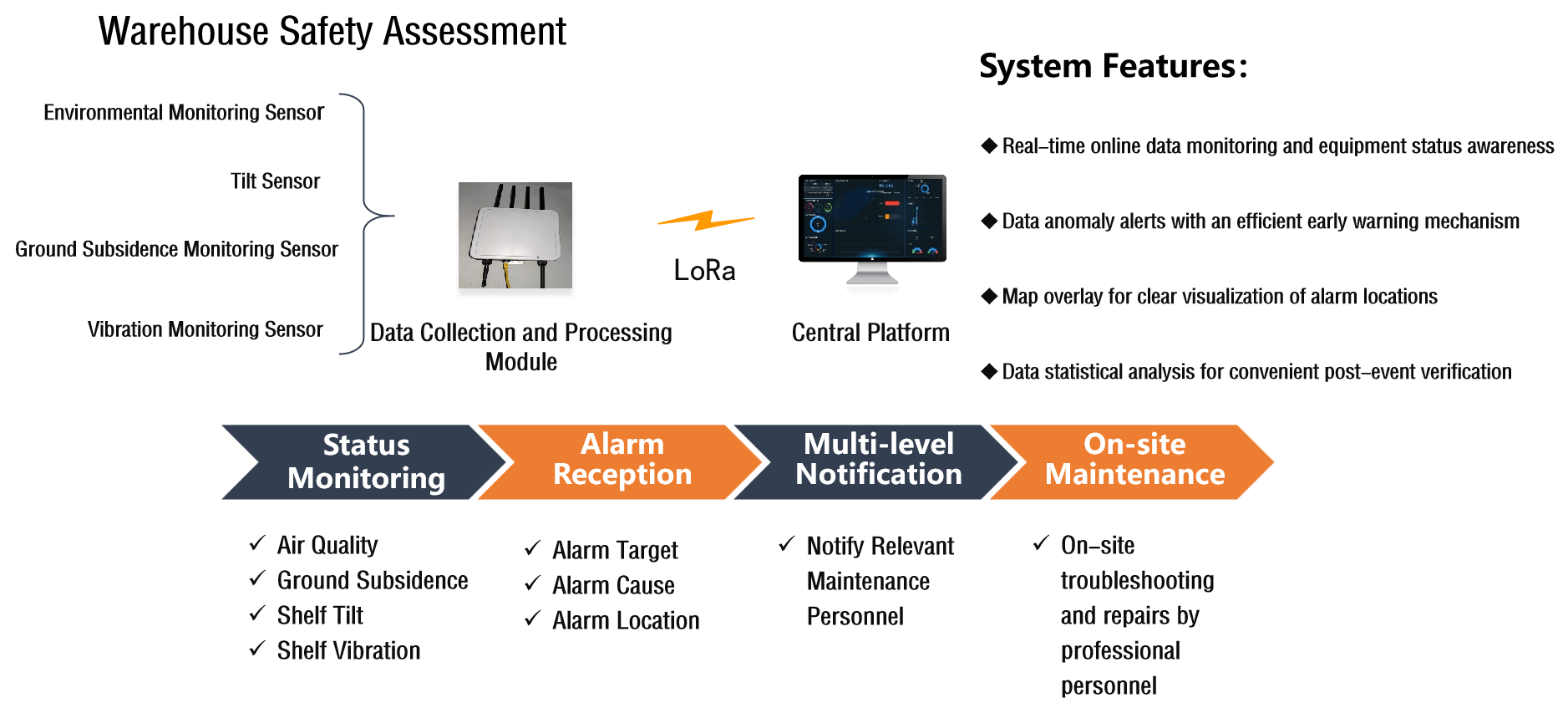

The three-dimensional warehouse safety monitoring system based on LoRa wireless network focuses on the safety of the three-dimensional warehouse shelf structure, abnormal vibration of the stacker, ground settlement and other safety events, and realizes the all-round and automatic monitoring of the safety of the three-dimensional warehouse.

The three-dimensional warehouse adopts a completely self-developed LoRa wireless network, which can better adapt to the application requirements of the three-dimensional warehouse security monitoring, obtain lower power consumption and cost, and facilitate the subsequent warehouse security monitoring and warehouse management business upgrades.

Based on the architecture of modular and standard interface design, the warehouse security monitoring software can be expanded with intelligent data processing and more business management modules to realize the predictive maintenance and monitoring and management of warehouse and storage equipment. Other extensibility features are as follows:

-

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia -

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety -

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir -

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a