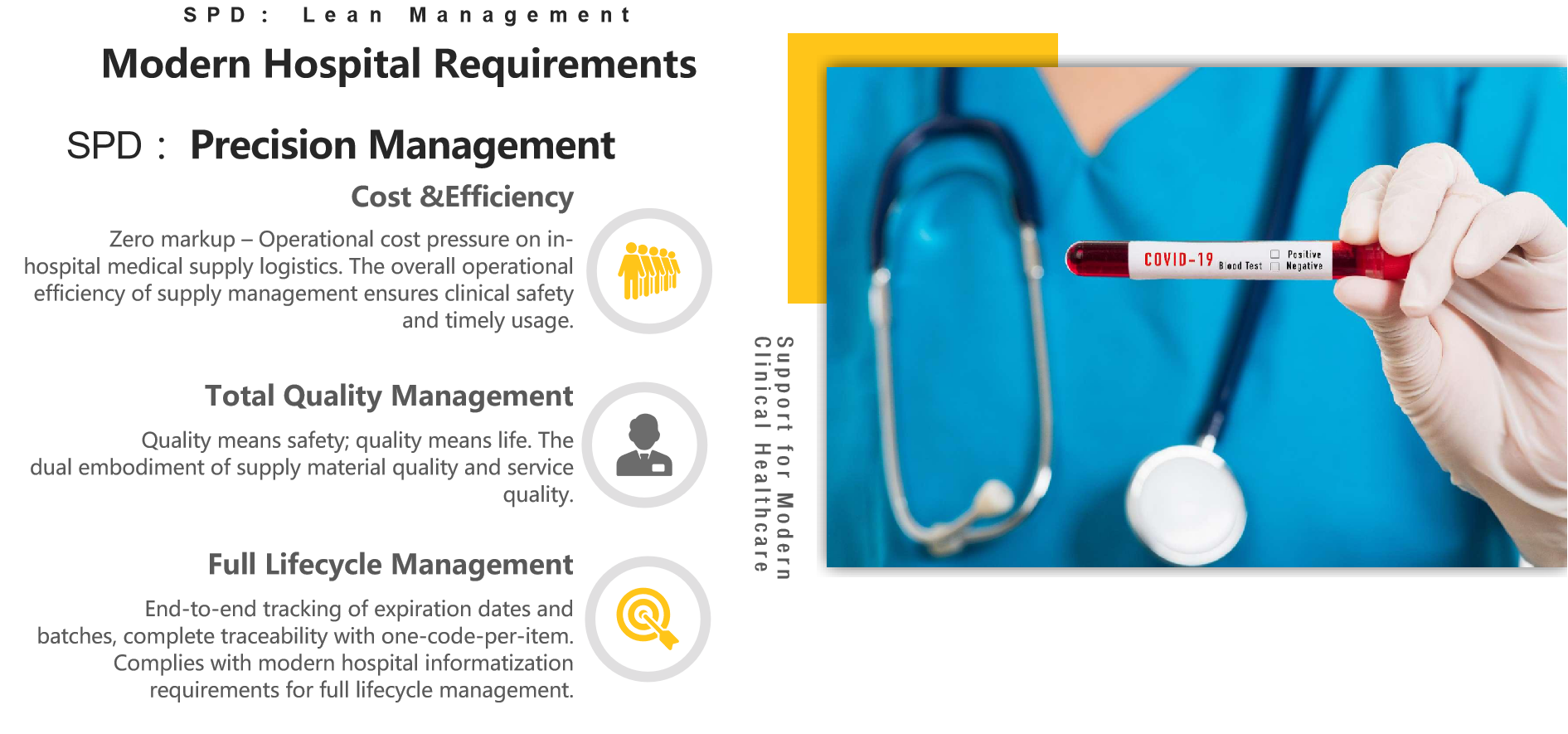

RFID Consumables Management in Medical SPDs: Revolutionizing the Management and Control of Medical Supplies

In the medical industry, the management of medical consumables is an important part of hospital operation management. With the continuous development of medical technology and the growing demand for medical services, the traditional medical consumables management model has gradually exposed many drawbacks. The combination of medical SPD (Supply Processing Distribution) mode and RFID (Radio Frequency Identification) technology has brought new changes to the management of medical consumables.

First, the dilemma of traditional medical consumables management

Under the traditional medical consumables management system, hospitals mainly rely on manual records and manual inventory from procurement, warehousing, storage to clinical use. In the procurement process, due to poor information communication, the number of purchases is often unreasonable, either the inventory backlog occupies a lot of funds, or the supply is insufficient to affect clinical treatment. When warehousing, manually check the type, quantity and specification of consumables, which is inefficient and error-prone. During the storage stage, it is difficult to grasp the inventory dynamics of consumables in real time, and it is impossible to find expired or damaged consumables in time. In the process of clinical use, the feedback of consumables use information lags behind, which is not conducive to cost accounting and optimal allocation of resources. These problems not only increase hospital operating costs, but can also have a negative impact on the quality of medical services.

Second, the principle and characteristics of RFID technology

RFID technology is a non-contact automatic identification technology that automatically identifies the target object and obtains relevant data through radio frequency signals. It consists of three parts: Tag, Reader, and Antenna. The label is attached to the identified object and stores the information of the target object; The reader reads the information in the tag and transmits the data to the backend system; The antenna is responsible for transmitting the RF signal between the tag and the reader. RFID technology has the characteristics of fast recognition, simultaneous identification of multiple objects, large data storage capacity, strong anti-interference ability, and long service life, which make it very suitable for medical consumables management.

3. Advantages of RFID application in medical SPD

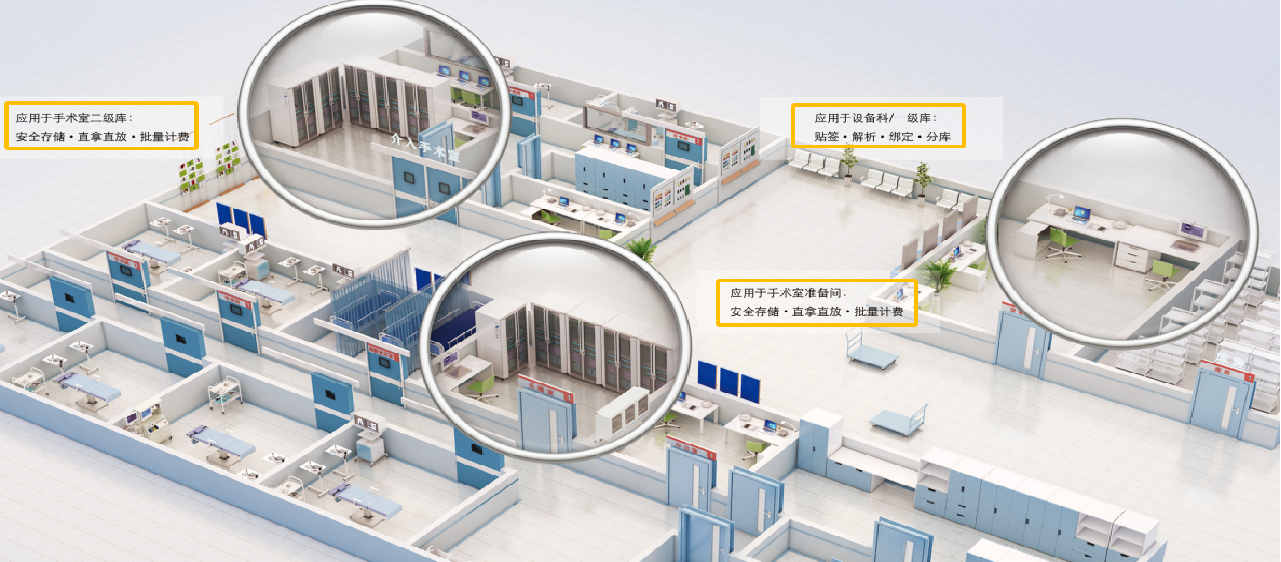

Precise inventory management: In the medical SPD mode, RFID tags are pasted on each medical consumable, and the location and quantity changes of consumables can be tracked in real time by deploying readers in key locations such as warehouses and departments. The hospital can accurately grasp the inventory dynamics, realize the "zero inventory" management concept, reduce the inventory backlog, and reduce the cost of capital occupation. At the same time, the system can automatically trigger procurement alerts according to the preset inventory threshold to ensure the timeliness of consumables supply.

Efficient supply chain collaboration: From suppliers to hospitals to clinical departments, RFID technology enables real-time sharing of information throughout the supply chain. Suppliers can use the system to understand the inventory and demand of the hospital in real time, arrange production and distribution in advance, and improve the response speed of the supply chain. The seamless connection of information between various departments within the hospital can also be realized, and the communication between procurement, warehousing and clinical departments is smoother, reducing work delays and errors caused by information asymmetry.

Full quality traceability: Each RFID tag records the detailed information of medical consumables, including manufacturer, production date, batch number, expiration date, etc. In the process of use, once there is a quality problem, by reading the label information, the source and flow direction of the consumables can be quickly traced, and recall or other treatment measures can be taken in time to ensure the safety and rights of patients.

Optimized cost accounting: RFID technology can accurately record the use of consumables, which can accurately calculate the cost of consumables for each department and each patient, and provide accurate data support for hospital cost accounting and performance appraisal. At the same time, it reduces the cost increase due to poor inventory management and waste, and improves the hospital's economy.

High-quality compliance management, covering medical consumables procurement, acceptance, warehousing, storage, inventory, application, delivery, clinical use, quality and safety reporting, adverse reaction consumables disposal, key varieties monitoring, key varieties of abnormal early warning, use evaluation and other links, to achieve the traceability of the whole life cycle of medical devices.

Benefits & Costs

Terminal use drives supply, precise distribution, post-use settlement builds reasonable inventory at all levels, reduces the backlog of materials and capital occupation, and allows medical staff to return to the medical profession itself.

-

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia -

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety -

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir -

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a