Introduction to RFID tool management application system in the field of automobile manufacturing

Background and current situation of the case

Facing challenges

Lack of unified management: the tool management process lacks standardization, and the consumable parts cannot be finely managed.

Complex management process: There are many types and quantities of tools, and the sending and receiving process is cumbersome.

Easy to omission and easy to lose: the use of tools and tools is scattered, and the collection personnel are complex, which is prone to omission and loss.

Inconsistency between accounts and facts: The status of the use of tools and tools is not updated in a timely manner, and the inventory workload is large and the frequency is low, resulting in inconsistent accounts and facts.

Solution: RFID-based tool management system

Real-time and accurate monitoring, all-round control of the dynamics of tools and tools: After each tool is installed with RFID tags, the system is like a "smart eye", which can capture key information such as the location and status of tools in real time and accurately. Whether stored in a tool cabinet or used on the production site, the status is under control. The traditional inventory work is time-consuming and laborious, and manual verification is prone to errors; Now, with the help of the real-time monitoring function of the system, the inventory can be quickly completed by batch reading, which greatly shortens the time, improves the accuracy of data, and ensures that all aspects of tool management are correct.

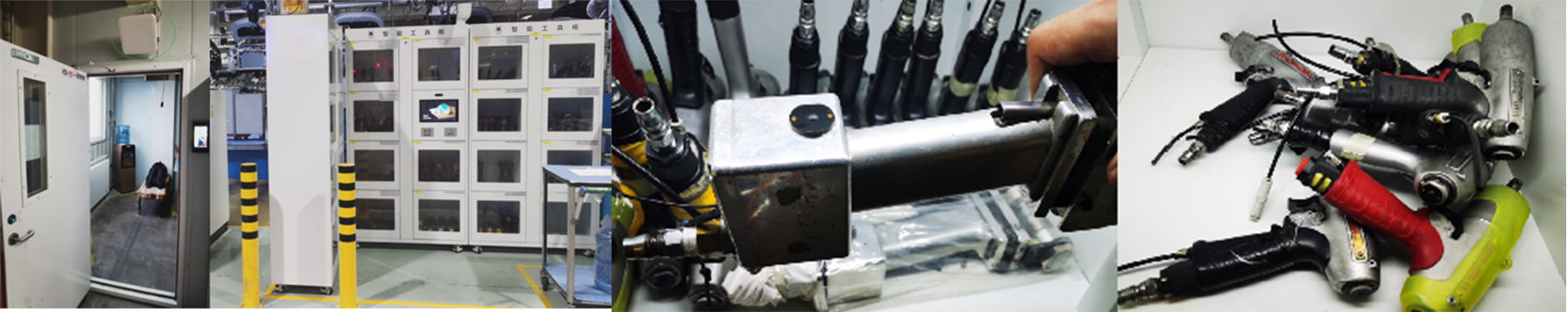

Streamlining the process and significantly improving work efficiency: In the past, the process of collecting and returning tools was cumbersome and labor-intensive. Today, the application of RFID smart tool cabinet and facial recognition login technology has completely changed this situation. The user can log in by swiping his face, and the system can complete the collection according to the simple operation process, and the system automatically records the collection information, without manual registration, greatly simplifying the workflow. This not only reduces the waiting time of production line workers, but also makes the production process more compact and efficient, providing a strong guarantee for the efficient production of enterprises.

Data-driven decision-making and optimal resource allocation: Data is the core asset of modern enterprise management. The system has powerful data collection, analysis and statistical functions, and can deeply mine multi-dimensional data such as the frequency of use of tools and tools, maintenance records, and service life. Through these data, enterprises can have a clear insight into the actual demand for tools and tools, scientifically and reasonably arrange procurement plans, avoid production delays caused by inventory backlog and shortage, and achieve optimal allocation of resources. At the same time, according to the data analysis results, the maintenance work is planned in advance, which can effectively extend the service life of tools and tools, reduce the operating costs of enterprises, and create greater economic benefits.

System integration to create a collaborative management ecosystem: In enterprise operation management, inter-departmental collaboration is crucial. The system can be seamlessly connected with multiple management functions such as production scheduling, tool tracking, equipment failure analysis, network reports, etc., and share a unified database. Production, maintenance, procurement, logistics and other related departments can obtain the latest information of tools and tools in real time, efficient information circulation breaks the information barriers between departments, makes collaboration smoother and more efficient, and the enterprise management model is more scientific and reasonable, laying a solid foundation for achieving intelligent manufacturing and intelligent management goals, and helping enterprises stand out in the fierce market competition.

Related Products

RFID Smart Tool Cabinet (S7)

RFID Handheld Terminal (M7S)

RFID Multi-Attribute Electronic Tag(T1515)

R5011 RFID electronic tag (R5011)

RFID tool management application system

-

RFID tool management in the field of automobile manufacturingIntroduction to RFID tool management application system in the field of automobile manufacturingBackground and current situation of the caseAn internationally renowned automotive factory has been faci

RFID tool management in the field of automobile manufacturingIntroduction to RFID tool management application system in the field of automobile manufacturingBackground and current situation of the caseAn internationally renowned automotive factory has been faci -

Laboratory weighing RFID management, assistant laboratory scientific research and efficient work!Lab: The E300S opens a new chapter in the convergence of weighing and RFID management1. Background of the caseIn today's era of rapid development of science and technology, the refinement and intellig

Laboratory weighing RFID management, assistant laboratory scientific research and efficient work!Lab: The E300S opens a new chapter in the convergence of weighing and RFID management1. Background of the caseIn today's era of rapid development of science and technology, the refinement and intellig -

Management of medical surgical instruments: intellectual innovation, breaking the game and increasing efficiencyMedical Surgical Appliance Management: Digital Intelligence Innovation, Breaking the Situation and Increasing Efficiency 1. Background of the case In the bright starry sky of the global

Management of medical surgical instruments: intellectual innovation, breaking the game and increasing efficiencyMedical Surgical Appliance Management: Digital Intelligence Innovation, Breaking the Situation and Increasing Efficiency 1. Background of the case In the bright starry sky of the global -

RFID management of edible product production line, efficient transformation of production lineThe S8080 industrial all-in-one machine helps the edible product production line to produce efficiently At a time when competition in the food production industry is fierce, major enterprises a

RFID management of edible product production line, efficient transformation of production lineThe S8080 industrial all-in-one machine helps the edible product production line to produce efficiently At a time when competition in the food production industry is fierce, major enterprises a