RFID helps the efficient operation of material inbound and outbound management

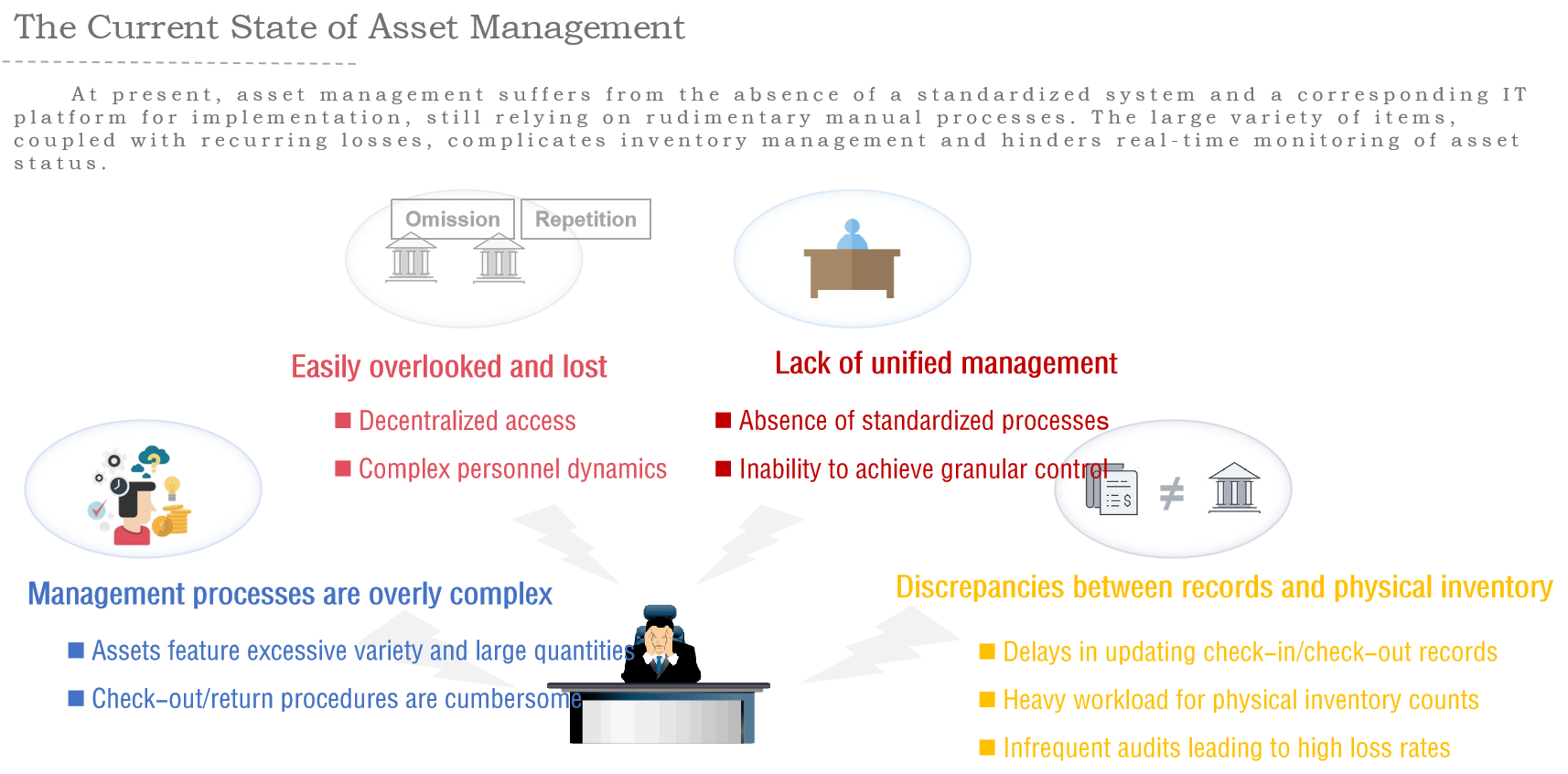

In today's competitive business environment, there are many complex challenges to managing operations. Among them, material management, as a key part of enterprise operation, has always been a difficult problem for enterprise managers to overcome in an orderly and efficient manner how to control a wide variety of materials and a large number of materials.

In the actual production operation, when the enterprise urgently needs to use a certain type of material, it must be able to quickly and accurately locate it, which not only tests the efficiency of material management, but also relates to whether the production can be smoothly promoted. At the same time, doing a good job in the prevention of loss and theft of materials, ensuring the safety of enterprise property, and laying a solid foundation for safe production are all important tasks that cannot be ignored in the operation of enterprises.

However, in the traditional maintenance management mode, it mainly relies on manual item screening and manual recording of inbound and outbound registration. When it comes to item screening, staff need to spend a lot of time and energy checking the type, quantity and status of materials one by one, which is not only inefficient, but also prone to errors due to human negligence. And manual warehousing registration, not only the process is cumbersome, easy to appear registration errors or omissions, but also extremely inconvenient when inquiring about the history of materials in and out of the warehouse. The efficiency and accuracy of these traditional management methods are far from meeting the expectations of managers for efficient operation of enterprises, and it is increasingly difficult to meet the efficient needs of modern enterprises for material management in a rapidly changing market environment.

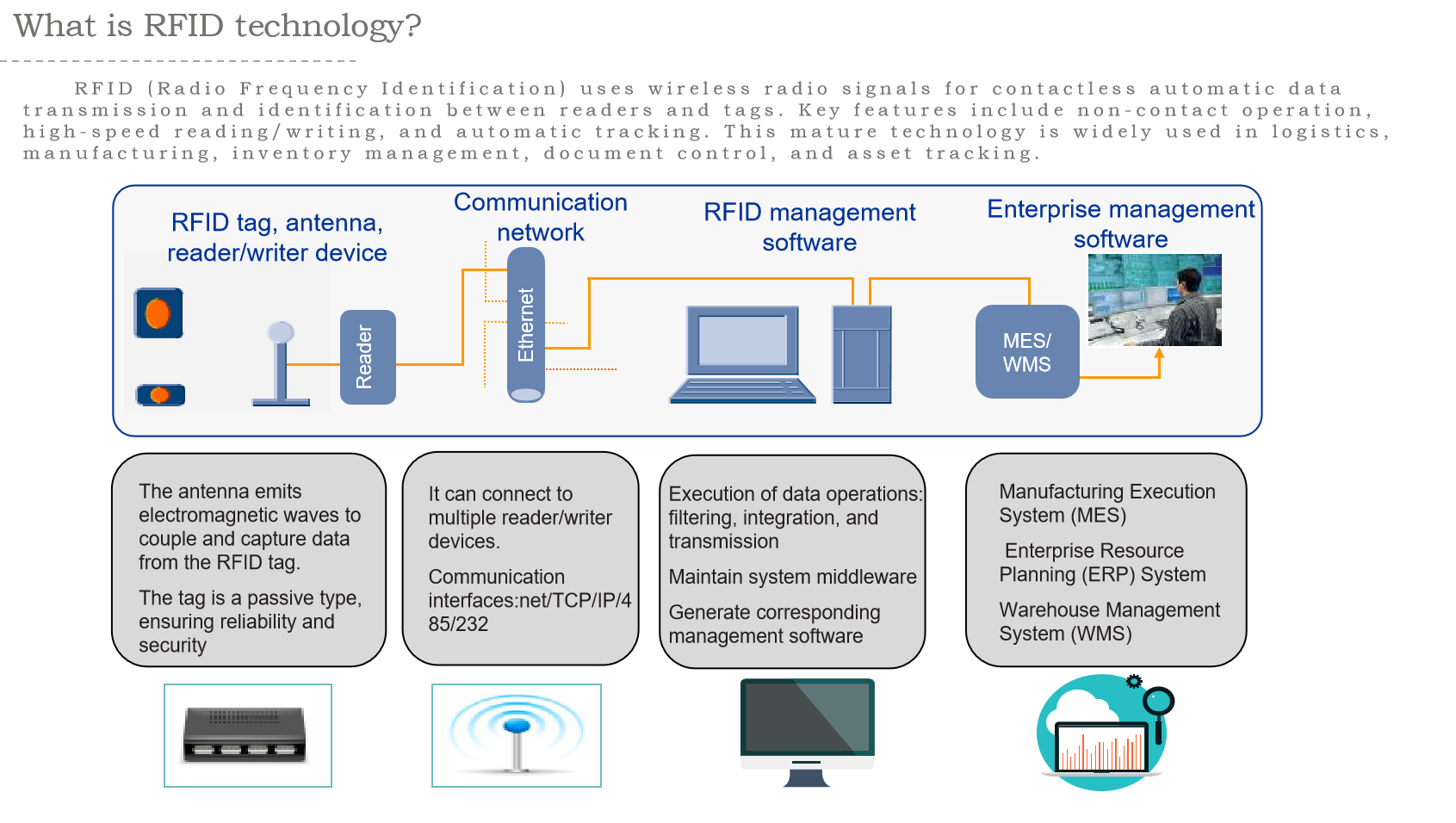

At this time, RFID technology has gradually become a powerful weapon to solve the problem of enterprise material management with its excellent performance advantages. RFID technology, that is, radio frequency identification technology, it has extremely high recognition accuracy, and can quickly and accurately identify target materials in a complex material management environment with a very low error rate. Its performance is stable and reliable, not disturbed by general environmental factors, and can work continuously for a long time to ensure the consistency of identification. In addition, the technology stores a huge amount of information and can record the detailed information of materials, including production batches, production dates, service life, etc., providing rich data support for the whole life cycle management of materials. In addition, it also has excellent oil resistance, water resistance, high temperature resistance and other characteristics, which makes it especially suitable for automatic identification scenarios in harsh working environments, whether it is in a humid warehouse or a production workshop with a lot of oil pollution, it can operate stably.

When enterprises introduce RFID technology, the level of warehouse management will be significantly improved in all aspects. In terms of preventing the loss and theft of materials, by pasting RFID tags on the materials and cooperating with the monitoring system, the system can issue an alarm in time once the materials are abnormally moved, effectively reducing the risk of theft and loss of materials. In the management of inbound and outbound storage, it greatly simplifies the traditional registration process, when materials enter and exit the warehouse, only through RFID reading and writing equipment, information collection can be quickly completed, without manual registration one by one, which greatly improves work efficiency. Not only that, it can also realize the automatic collection and intelligent processing of item information and the automatic output of reports. The system can collect various data of materials in real time, analyze and process them according to preset programs, and generate various detailed reports, such as inventory reports, warehousing reports, etc., to provide intuitive and accurate data support for enterprise managers, help managers make scientific decisions, create a more intelligent and efficient management system for enterprises, and help enterprises stand out in the fierce market competition.

High-performance read/write device system

The built-in 4-8 high-sensitivity monostable RF ports provide the highest RF sensitivity needed for maximum accuracy and longer read ranges, resulting in the highest throughput in its class.

RFID Directional Fractal Antenna Array Deployment System

The industry's highest-performance parting RFID antenna array system is adopted, which has accurate identification, controllable beam, and superior high-speed reading performance in the specified domain.

Scalability

The main control computer adopts an industrial touch screen all-in-one machine, which has good stability, high reliability and strong scalability; Windows (optional Android) system environment, providing API interface, docking with the existing warehouse management system information.

Good anti-interference

The system uses multi-channel sensors as the working logic of the trigger system, which effectively prevents personnel from passing through the reading by mistake. The tag sensing antenna has the characteristics of high gain and low standing wave, and adopts multi-antenna controllable tag identification range.

Visual broadcasting

A variety of real-time status sound and light alarm and voice broadcast functions can be set to facilitate business personnel to understand the working status in time.

-

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia -

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety -

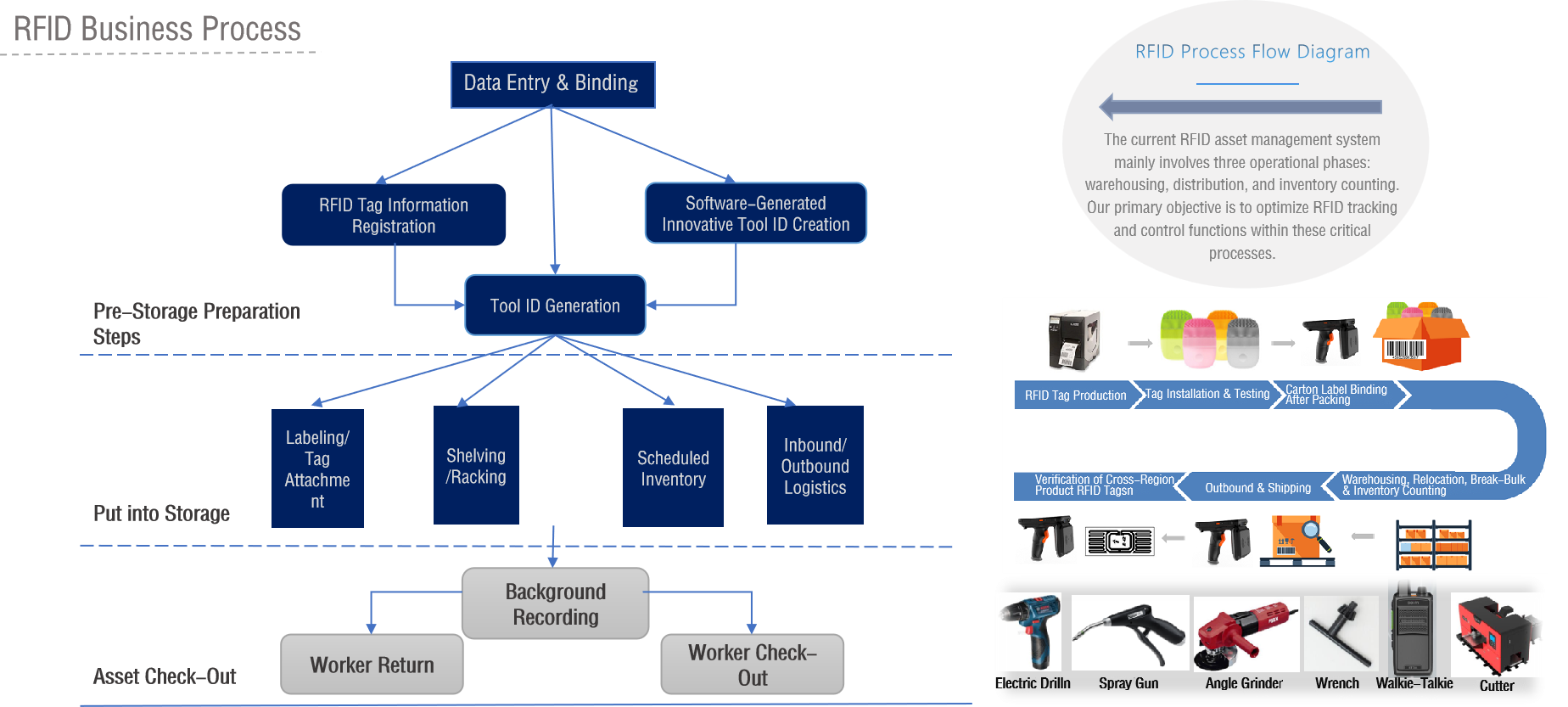

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir -

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a