RFID technology opens a new era of tool management

In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level directly affects the work efficiency and operating costs of enterprises. However, there are still many problems in the management of tools and tools in many enterprises, and effective solutions are urgently needed.

First, the dilemma of traditional tool management

Lack of a unified standard system: At present, there is a lack of a unified standard system for the management of tools and tools, and there is no unified standard for the classification, numbering, and use specifications of tools and tools between various enterprises and even different departments within the enterprise.

Inefficient manual management: Most enterprises are still in the initial stage of manual management of tools. Manually record the requisition, return, inventory and other information of tools and tools, and it is impossible to grasp the status of tools and tools in time.

A wide variety of items: the variety and quantity are constantly increasing, and in the face of a large number of items, it is difficult for manual management to achieve comprehensive and meticulous management

Serious loss: lack of effective 1, loss is not a few, not only increase the cost of procurement, but even affect the progress of production.

2. Brief description of RFID technology

As one of the product areas that have developed rapidly in recent years, RFID smart devices provide new ideas for solving the above problems. RFID (Radio Frequency Identification) technology, also known as radio frequency identification technology, is a non-contact automatic identification technology. It automatically identifies the target object and obtains relevant data through RF signals, without manual intervention, and can work in various harsh environments. RFID technology combines the integration of a variety of electronic products from the physical structure design to form a solution device product that meets the needs of specific scenarios. This feature not only reduces the difficulty of project implementation for integrators, but also greatly improves the user experience, promoting the rapid development of RFID technology in multiple industries.

3. The application advantages of RFID in tool management

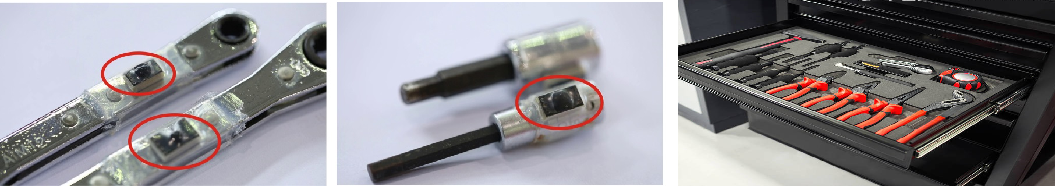

1. Unified standards and standardized management: Using RFID technology, a unified tool management standard system can be established. Give each piece of tool a unique RFID tag that records details such as the name, model, specification, department, and expiration date of the tool. Through this unified logo, the standardized management of tools and tools is realized.

2. Real-time monitoring and precise positioning: RFID readers can be deployed in key locations such as warehouses and workshops within the enterprise to obtain the location information of tools and tools in real time. When the tools are used and returned, the system can automatically record relevant information, and managers can query the status of tools and tools through the system at any time, including their location, users, use time, etc., to achieve real-time monitoring and accurate positioning of tools.

3. Efficient inventory and improved accuracy: Traditional manual inventory methods are inefficient and error-prone. When using RFID technology for inventory, you only need to use a handheld RFID reader to scan in the warehouse or work area, and you can quickly obtain the information of all tools and tools, which greatly improves the efficiency and accuracy of inventory. The system can also automatically generate inventory reports, which is convenient for managers to analyze data and make decisions.

4. Anti-loss and anti-theft, reduce costs: RFID technology can set up an alarm function, when the tool is taken out of the specified area without authorization, the system will immediately send out an alarm, effectively prevent the loss and theft of the tool. By reducing the loss of tools, the procurement cost of the enterprise is reduced and the economic benefits of the enterprise are improved.

Finally, the RFID asset management system realizes the positioning and tracking of enterprise assets through RFID technology, establishes an advanced RFID application system in key links, improves the informatization, automation, networking and intelligence of asset management, achieves the purpose of consistent accounts, standards and things, improves the efficiency of asset inventory, and facilitates the management department to grasp the asset dynamics in real time and accurately.

Through effective monitoring and management, enterprises can save a lot of manpower and material resources, improve asset utilization, and at the same time combine with their own business platforms to standardize internal asset processes, minimize operating costs and risks, and enhance comprehensive competitiveness.

-

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia

RFID power material in and out of the warehouse management efficient operationRFID helps the efficient operation of material inbound and outbound managementIn today's competitive business environment, there are many complex challenges to managing operations. Among them, materia -

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety

LoRa sensor on-line monitoring makes library safe production saferThe online monitoring of LoRa+ sensors makes the safe production of the warehouse saferThe guardian of the safety of large vertical shelvesIn the modern logistics and warehousing industry, the safety -

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir

RFID Technology Opens a New Era of Tools ManagementRFID technology opens a new era of tool management In the operation of modern enterprises, tools and tools are an important foundation for production and maintenance, and their management level dir -

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a

Introduction to the Application of RFID Enabling Tobacco Industry in Various FieldsRFID empowers the application of various fields in the tobacco industryIn accordance with the idea of lean management, make full use of the technology of "digitalization, automation, informatization a