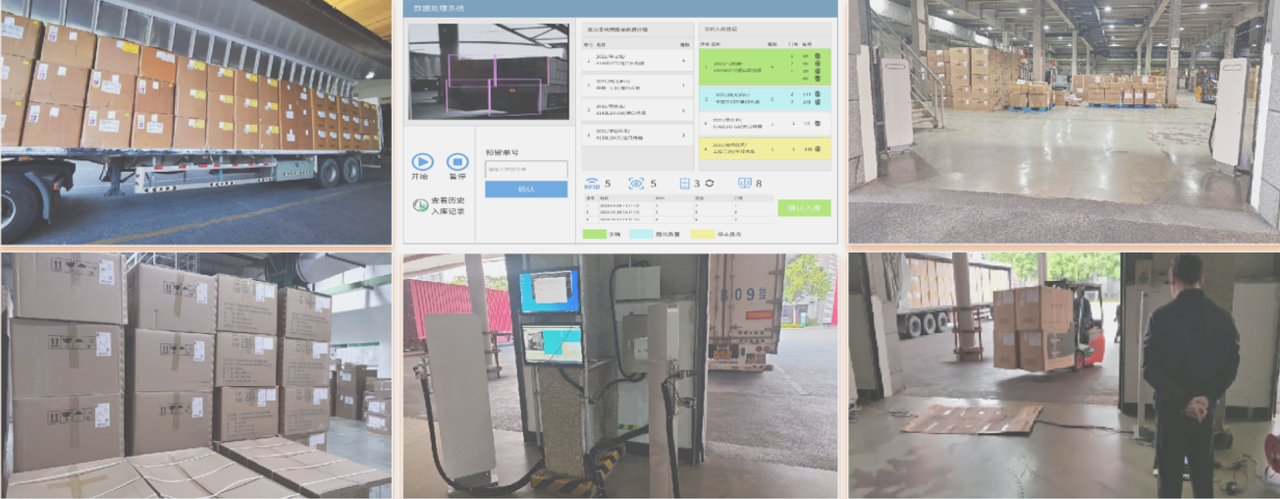

Tobacco RFID batch traceability management: opening a new chapter in intelligent management and control of the tobacco industry

1. Background of the case

In the increasingly fierce competition in the tobacco industry, improving product quality and refined management has become the key to the development of enterprises. XX China Tobacco Industry Co., Ltd. actively conforms to the trend of the times and plans to build a comprehensive and whole-process batch traceability system with the help of cutting-edge technologies such as RFID and QR code. This system aims to deeply connect the core business links such as R&D, procurement, production, sales, and logistics in the supply chain, and achieve real-time monitoring and accurate traceability of the whole business process from the source of raw materials to the output of finished cigarettes. Through this initiative, enterprises can timely gain insight into and improve various quality problems in the production process, further strengthen the process quality control capabilities, and strive to make products better and better, thereby greatly enhancing brand value and enhancing market competitiveness.

Second, facing challenges

With the continuous expansion of enterprise business scale, the disadvantages of the original barcode-based management system have become increasingly prominent. Barcodes are not resistant to dirt, and in complex production and storage environments, it is easy to fail to read information due to stains and wear. Its data storage capacity is extremely limited, which is difficult to meet the growing demand for product information recording; The reading interval is short, which is inefficient during large-scale material inventory; And it cannot be read in batches, and the code needs to be scanned one by one, which consumes a lot of manpower and time. These deficiencies bring great inconvenience to the traceability of material management, which in turn leads to a series of serious problems. The number of assets is large and the management is chaotic, the financial information of stock assets and incremental assets is distorted, the accounting of materials and raw materials is seriously inaccurate, and even the loss of assets. At the same time, the direction of material traceability is ambiguous, the person responsible for processing is difficult to determine, and the material traceability is difficult, and the enterprise needs to invest a lot of time and labor costs to carry out related work, which seriously restricts the efficient operation and development of the enterprise.

3. Solution

In the actual operation process, a professional RFID tag printer is used to clearly present the label information in a visual way, which is convenient for staff to quickly identify and check. At the same time, the high-performance RFID handheld terminal S61 uses advanced radio-magnetic wave technology to efficiently collect data from tags. In the production process, staff can report the registration status of the production process in a timely manner through S61 to ensure that the entire production and operation process is transparent and controllable, and once a problem occurs, it can be quickly traced back to the source of the problem and effective measures can be taken to solve it in time.

Fourth, the product involved

-

RFID tool management in the field of automobile manufacturingIntroduction to RFID tool management application system in the field of automobile manufacturingBackground and current situation of the caseAn internationally renowned automotive factory has been faci

RFID tool management in the field of automobile manufacturingIntroduction to RFID tool management application system in the field of automobile manufacturingBackground and current situation of the caseAn internationally renowned automotive factory has been faci -

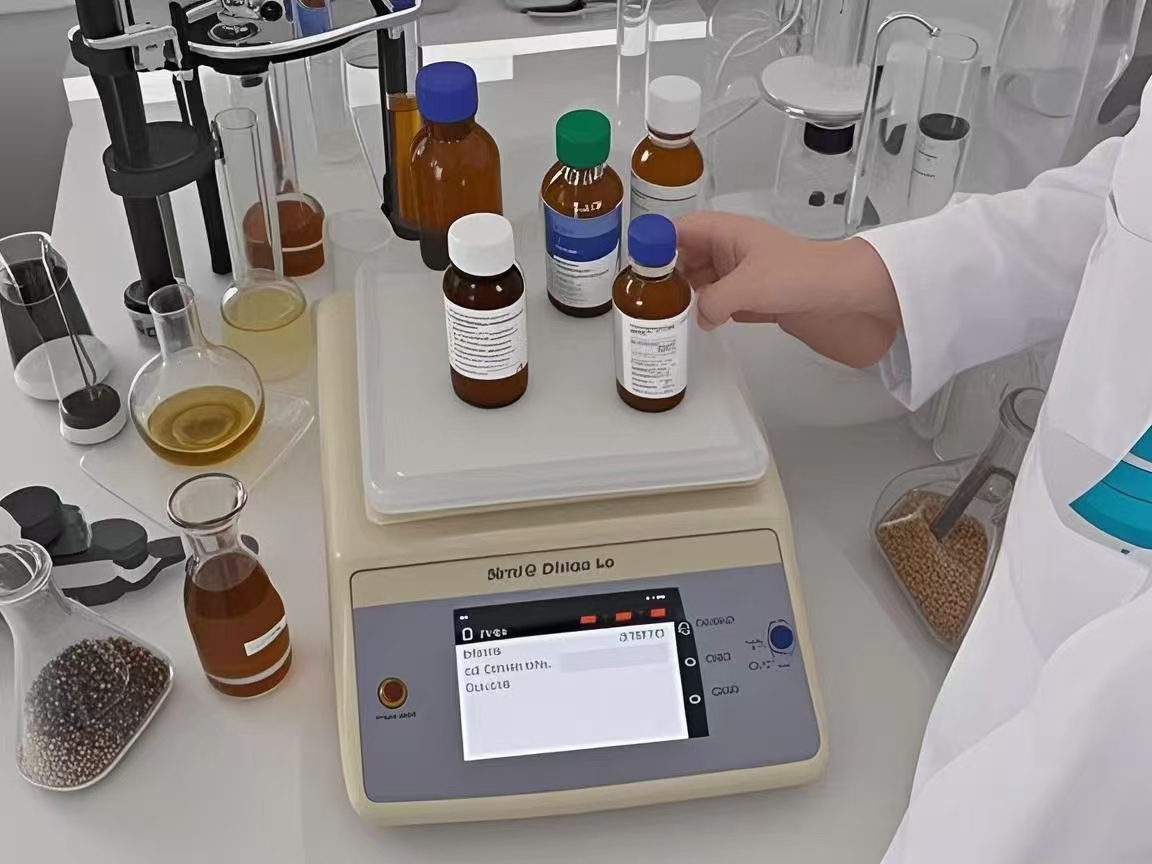

Laboratory weighing RFID management, assistant laboratory scientific research and efficient work!Lab: The E300S opens a new chapter in the convergence of weighing and RFID management1. Background of the caseIn today's era of rapid development of science and technology, the refinement and intellig

Laboratory weighing RFID management, assistant laboratory scientific research and efficient work!Lab: The E300S opens a new chapter in the convergence of weighing and RFID management1. Background of the caseIn today's era of rapid development of science and technology, the refinement and intellig -

Management of medical surgical instruments: intellectual innovation, breaking the game and increasing efficiencyMedical Surgical Appliance Management: Digital Intelligence Innovation, Breaking the Situation and Increasing Efficiency 1. Background of the case In the bright starry sky of the global

Management of medical surgical instruments: intellectual innovation, breaking the game and increasing efficiencyMedical Surgical Appliance Management: Digital Intelligence Innovation, Breaking the Situation and Increasing Efficiency 1. Background of the case In the bright starry sky of the global -

RFID management of edible product production line, efficient transformation of production lineThe S8080 industrial all-in-one machine helps the edible product production line to produce efficiently At a time when competition in the food production industry is fierce, major enterprises a

RFID management of edible product production line, efficient transformation of production lineThe S8080 industrial all-in-one machine helps the edible product production line to produce efficiently At a time when competition in the food production industry is fierce, major enterprises a