RFID passive Internet of Things industry, what are the technical keywords that are stuck in the neck?

For example, Bluetooth technology has an annual market shipment of about 6 billion; NB-IoT, with an annual shipment volume of about 100 million. And when many people predict the future potential, they also like to quote the future of 50 billion, or even 100 billion connections per year.

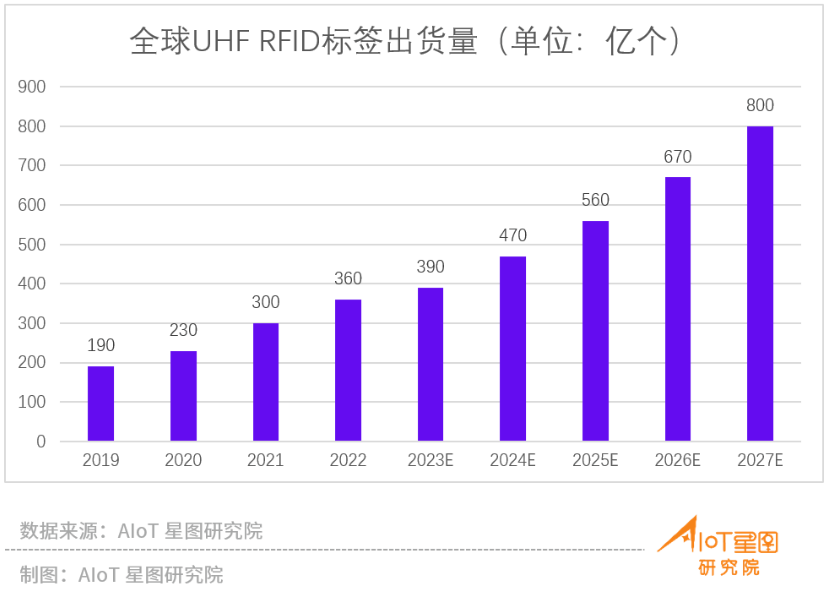

According to the latest research by AIoT Star Map Research Institute, global UHF RFID tag shipments have reached 36 billion in 2022.

Friends who are familiar with RFID should know that as one of the earliest commercial IoT technology, the RFID industry has been relatively mature, and as early as more than 10 years ago, the annual tag shipments exceeded 10 billion, normally speaking, when an industry base is very large, its growth rate will be reduced, but the number of RFID passive Internet of Things connections is showing a trend of accelerated growth, which is enough to show that the annual connection of hundreds of billions of dollars is by no means its end.

Often a single project will have a huge consumption of RFID tags, such as:

-

Walmart currently consumes more than 10 billion RFID tags every year, and this is only used in some of Walmart's products, and the region is only in North America;

-

UPS uses about 50-6 billion RFID tags every year, while the number of express packages in China exceeds 110 billion every year;

-

Decathlon, ZARA, Uniqlo, Nike and other footwear and clothing brands consume 1 billion RFID tags every year.

It can be seen that RFID tags as consumables, as long as they are used in certain fields or some customers, its growth numbers are very huge.

What are the technologies that are stuck in the fast-growing RFID industry?

The industry is thriving, and the progress of technology is indispensable, because the progress of technology will promote the cost-effective improvement of RFID tags and give the industry a broader space for development.

So what are the technologies that are stuck in the RFID industry now?

The first one is the chip.

The importance of chips is self-evident, the same is true in the RFID industry, taking the most widely used UHF RFID as an example, the cost of a UHF RFID inlay accounts for more than 50%, and the sensitivity, capacity, stability and other indicators of the chip determine the success or failure of the project.

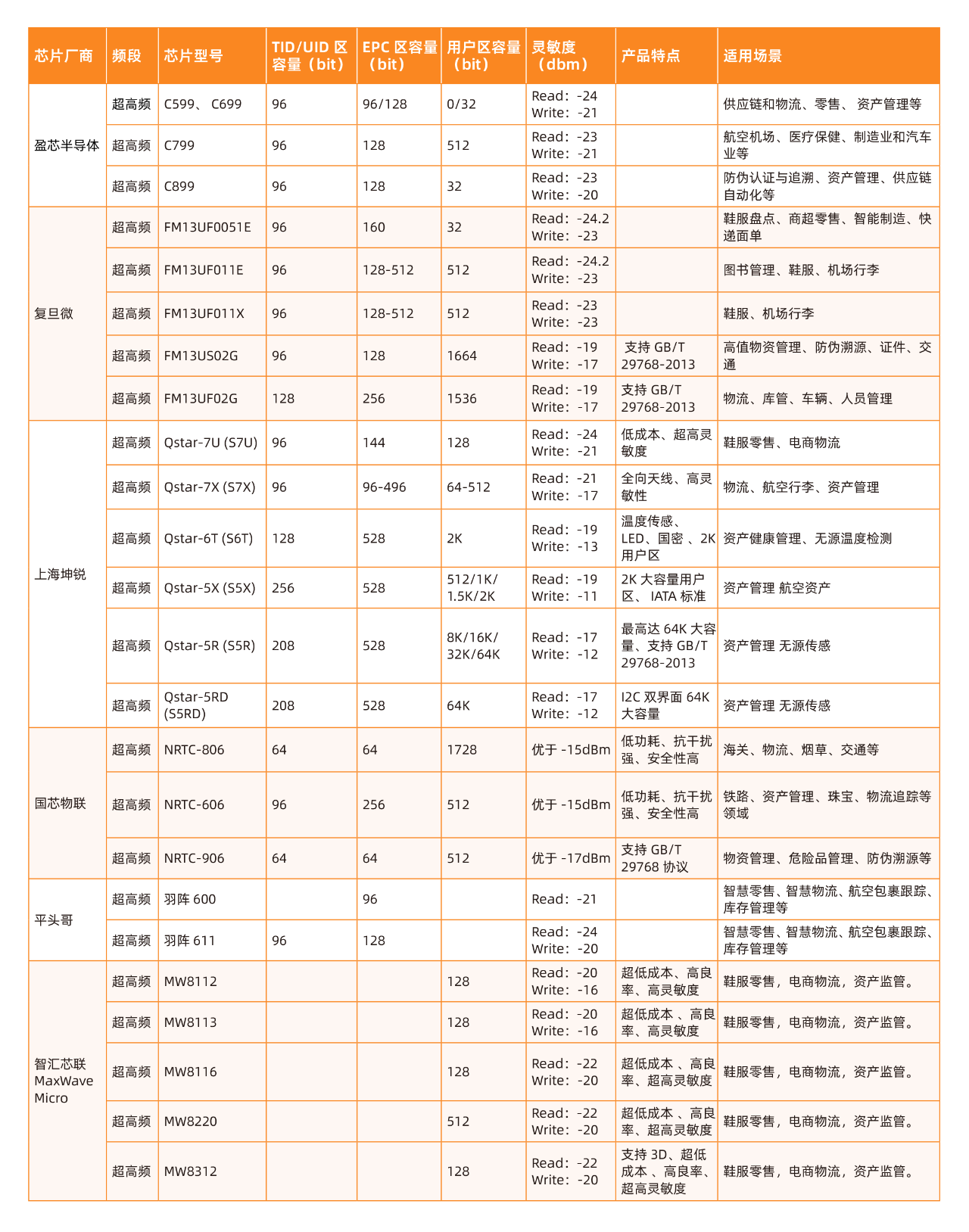

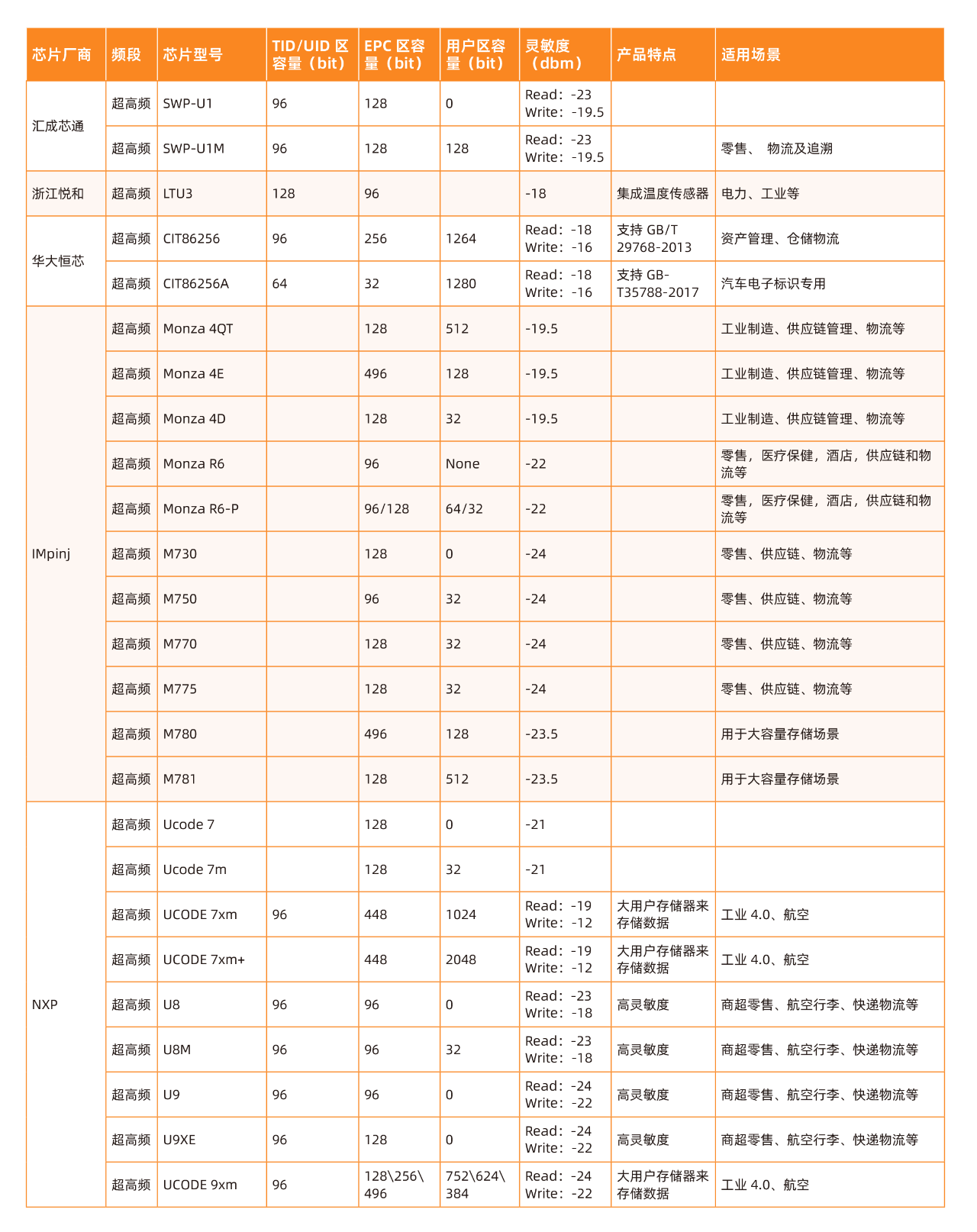

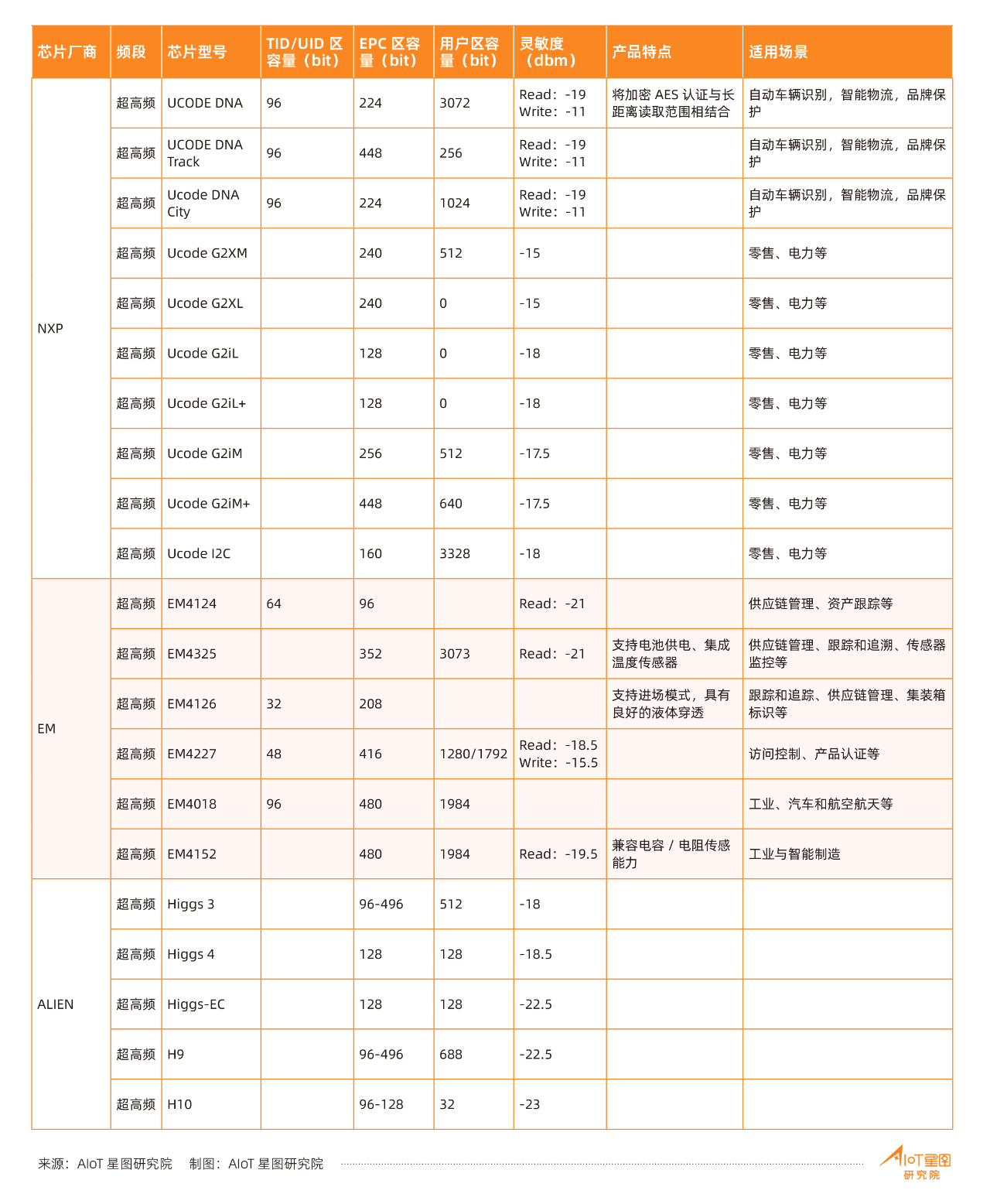

At the chip level, the industry has made significant progress in recent years, especially the rapid rise of domestic chip players. In the latest "2023 China RFID Passive Internet of Things White Paper", AIoT Xingtu Research Institute has sorted out all chip players and chip products in the market.

Just taking UHF RFID chips as an example, we can see the prosperity of the market.

For more information about RFID chips, please pay attention to the "2023 China RFID Passive Internet of Things Industry White Paper".

The second is the packaging equipment.

In the production of UHF and HF tags, there is a very core equipment, that is, the packaging equipment (also called the binding machine), the label is a very production-oriented link, and millions or even tens of millions of packaging equipment is the core of production, its function is to package the RFID chip and the tag together, become an inlay.

Because the size of the RFID tag chip is very small, the accuracy of the equipment is very high, in addition, the capacity efficiency is the core indicator of the production equipment, and it needs to be high in order to meet the requirements of mass production, and at the same time, it is also necessary to ensure the performance of the product.

At present, the packaging equipment on the market is dominated by the German manufacturer Newbao, among the domestic players, Xinjinglu also has more shipments in the market, in addition, there are also a number of new players entering this market, detailed players can refer to the industry map in the "2023 China RFID Passive Internet of Things White Paper".

The third is conductive adhesive.

Conductive adhesive refers to the glue that pastes the RFID chip and the antenna together, a kind of consumables for label production, and it is also a typical neck technology in the industry.

According to our calculations, one gram of conductive adhesive can make about 2-30,000 labels, with a total of 36 billion labels, about 1.5 million grams of conductive adhesive need to be used every year, and the price of each gram of conductive adhesive is more than 100 yuan, and the annual consumption amount of conductive adhesive is about 150-200 million, and as a consumable, this number will increase every year, which is also an important part of the cost of labels.